Vertical Integration Becomes Key Strategy for Motor Rotor Stator Manufacturers

As demand soars for electric motors across industries, manufacturers are embracing vertical integration to maintain control and efficiency. For motor rotor stator producers, owning every stage of production is fast becoming essential for success.

Electric Motor Surge Requires Smarter Manufacturing

From electric vehicles and industrial automation to wind turbines and home appliances, electric motors are more critical than ever. These systems rely heavily on the precision and performance of their core components—particularly laminated rotor cores and stator laminations.

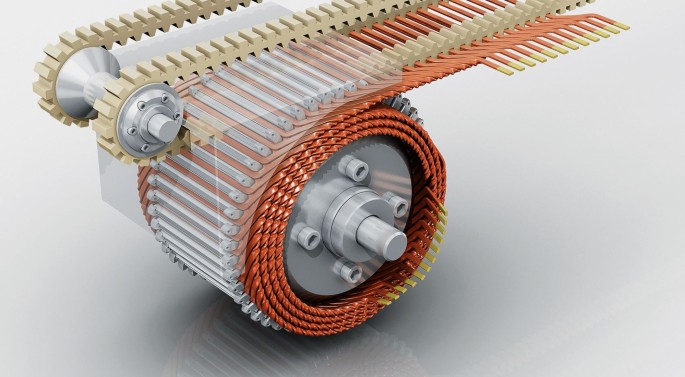

motor rotor stator assemblies are the heart of motor efficiency. Every aspect of their construction, from the material used to the accuracy of laser cut stator laminations, influences overall performance. Manufacturers seeking to lead in this field must now go beyond simple part assembly; they must command the entire value chain.

Vertical Integration Defined and Why It Matters

Vertical integration is the practice of consolidating multiple stages of production under one organization. For rotor and stator manufacturers, this means overseeing everything from raw material sourcing and lamination stamping to rotor assembly and final testing.

This method does away with the necessity for outside suppliers for crucial components like stator stacks or laminated rotor cores. It enhances agility, reduces lead times, and strengthens the ability to respond to customer demands or design changes with speed and accuracy.

Laser Cut Precision: The Backbone of Efficiency

The use of laser cut stator laminations has grown rapidly, thanks to their superior dimensional accuracy and ability to minimize eddy current losses. Laser cutting allows for intricate slot shapes and tighter tolerances, which boost the magnetic efficiency of the stator core.

By controlling this step in-house, manufacturers can avoid delays caused by outsourcing and can maintain tight quality control. This directly contributes to motor performance and consistency across production batches. Vertical integration ensures that these critical tolerances are met without compromise.

Laminated Rotor Core: A Central Performance Element

The laminated rotor core is another essential component that benefits from vertical integration. Manufacturers can improve motor efficiency by reducing energy losses from eddy currents by stacking thin sheets of electrical steel.

When the rotor core is produced externally, risks such as poor bonding, alignment issues, or substandard materials may arise. But in-house production enables close inspection, material control, and advanced bonding techniques—ensuring that the laminated rotor core meets strict performance requirements.

In advanced motor applications such as those found in drones, electric vehicles, and factory automation, even slight variations in rotor assembly can degrade motor output. Integrated manufacturers ensure higher consistency and reliability.

Reducing Supply Chain Complexity and Risk

Global disruptions, from geopolitical tensions to raw material shortages, have made businesses reconsider their reliance on complex supply chains. For motor manufacturers, this is especially critical. Delays in receiving stator laminations or rotor components can halt entire production lines.

Vertical integration reduces these risks significantly. By producing laser cut stator laminations and assembling laminated rotor cores internally, companies are less affected by external shocks. They gain a resilient, end-to-end production model that ensures faster delivery and improved inventory control.

Customization and Innovation Become Easier

Another advantage of vertical integration is design flexibility. It is possible to test and implement design iterations more rapidly when all procedures are internal.

This is especially important in the development of custom motor rotor stator designs for niche applications. Whether it’s adapting to non-standard slot profiles or developing quieter, cooler-running motors, vertically integrated teams can prototype and produce with agility.

Incorporating feedback from R&D, quality control, and production under one roof fosters a culture of rapid innovation. It speeds up product development and breaks down communication silos.

Investments in Automation and Smart Manufacturing

To support vertical integration, many manufacturers are investing in Industry 4.0 technologies. These include automated lamination stacking systems, robotic rotor assembly stations, and smart inspection systems for inline defect detection.

Laser-cutting stations are now integrated with real-time monitoring systems to ensure every stator lamination meets the required specs. Similarly, automated presses reduce human error while increasing speed and accuracy in the production of rotor cores.

These technological advancements are only feasible and sustainable when companies have full ownership of the processes—highlighting another benefit of vertical integration.

Setting the Competitive Standard

Industry leaders have already adopted vertical integration as a key strategy to differentiate themselves. Whether targeting the electric vehicle market or precision motion control in robotics, vertically integrated firms are able to offer better pricing, faster delivery, and superior quality.

These manufacturers are shaping the future of motor technology by investing in long-term capabilities—especially in the production of motor rotor stator components, laminated rotor cores, and laser cut stator laminations.

Conclusion: A Strategic Move Toward Control and Growth

For contemporary motor rotor and stator producers, vertical integration is a strategic necessity rather than just a fad. With full control over laminated rotor core construction and laser cut stator laminations, companies are not just building motors—they’re building the future of efficient motion systems.